By Jeff Scott

Manufacturing at any level is complex. With hundreds of industries and countless thousands of processes, gaining the experience required to succeed takes time and patience. For those choosing to manage within manufacturing, one of the earliest skills learned is the appreciation of and adherence to process, repetition, and metrics to guide their decision-making and build experience in how to respond when problems arise.

But startup manufacturing operations require a different managerial skillset altogether. Many of the support structures in the form of established and optimized procedures are either in skeletal form, or non-existent, requiring the manager to be both operations lead as well as project manager, process designer and a host of other duties.

In fact, many mainstream managers from established production operations can’t function in “alternative realities” such as startup and turnaround companies because these skillsets are so vastly different for success. For those looking to be successful in a startup manufacturing operation, or for leaders who are looking for that key manager to build and scale their operation, here are several ways to be successful as a startup manufacturing manager:

Think “Off the Shelf”

Forget the old cliché’ of thinking “Out of the Box”. As a manager in a startup manufacturing company, there is no box. You may find yourself in an empty factory with everyone asking “OK, what next”? Or you may find yourself with a conglomeration of equipment, plans and ideas that clearly won’t fly. And it is almost a given that as a startup, the company will produce products or devices for which no OEM equipment exists.

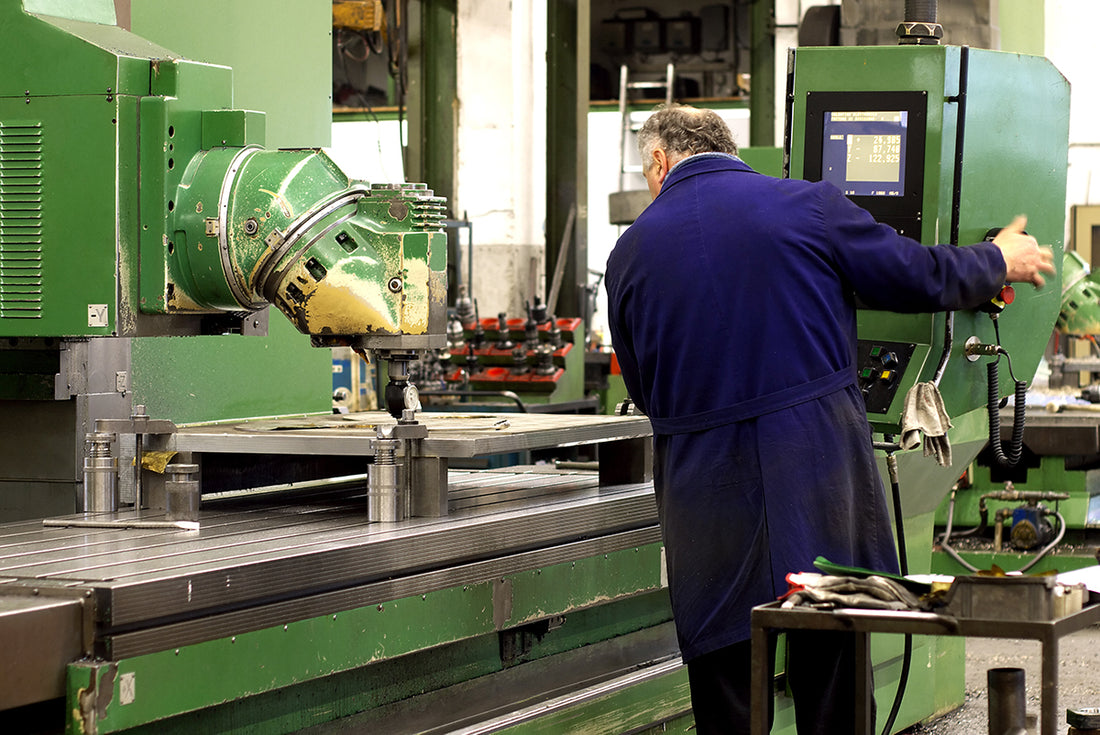

To succeed in manufacturing in a startup, managers must be inventive enough to think “Off the Shelf”. This means cobbling and assembling pieces of equipment together that you would never have imagined in traditional manufacturing. It also means repurposing equipment that is close to what you want to make it perform as needed. Thinking off the shelf in a new process can help pull together equipment that can become the standard for that industry down the road.

Iterate Like an Artisan

Often, what is to be produced is going form small lot, garage style, or one-off production to a full-scale manufacturing system. As production processes come together, there will be a lot of changes. Being able to iterate on the fly means a lot of trial and error, a lot of questions to vendors to keep from buying equipment you don’t need, and a lot of napkin sketches and handwork. Managers must be comfortable with rapid iterations for both core products, new products, and process changes.

Pivot Til’ You’re Dizzy

It is normal in a startup for the manufacturing manager to be the project manager, dock hand and capex purchasing planner. This means that pivoting from day to day is critical for success. Traditional manufacturing managers benefit from an established structure. In the realities of a startup, they are tasked with building the structure for others to learn from.

Introducing Mr. Macro Micro

Because a startup manager will need to map out precise SOPs for every conceivable process, it is important to they be able to focus in a detailed and linear scale at the micro level. Well documented processes can be lengthy and can make the difference with shorter and safer training times. Yet, they must also understand that there are times they will need to break away from the linear micro focus and zoom up to enterprise level to participate in macro issues such as product positioning, new product lines, policy discussions, and general and administrative tasks such as vendor vetting, purchasing, and hiring. The successful startup manufacturing manager will act like a zoom lens, capable of zooming into the detail and out to a broader level at a moment’s notice, something many traditional managers struggle with.

The skillset required to manage in a manufacturing startup operation is different than the one required for traditional processes, at least until the new operation settles and begins to optimize. Many from those established environments are not ready for the challenges of a startup, having relied on structure for most of their career.

The above thoughts point to a skillset that requires broad general knowledge about many processes and subject areas as well as one that requires a high degree of flexibility. It requires the agility to change direction without being thrown off course. And it also requires a mindset that embraces change rather than one that seeks a steady state. That…and really comfortable shoes.